Our advantages

Expertly Crafted Safe + Digital Pig Farms

Poultry Laying System

Pig Field System

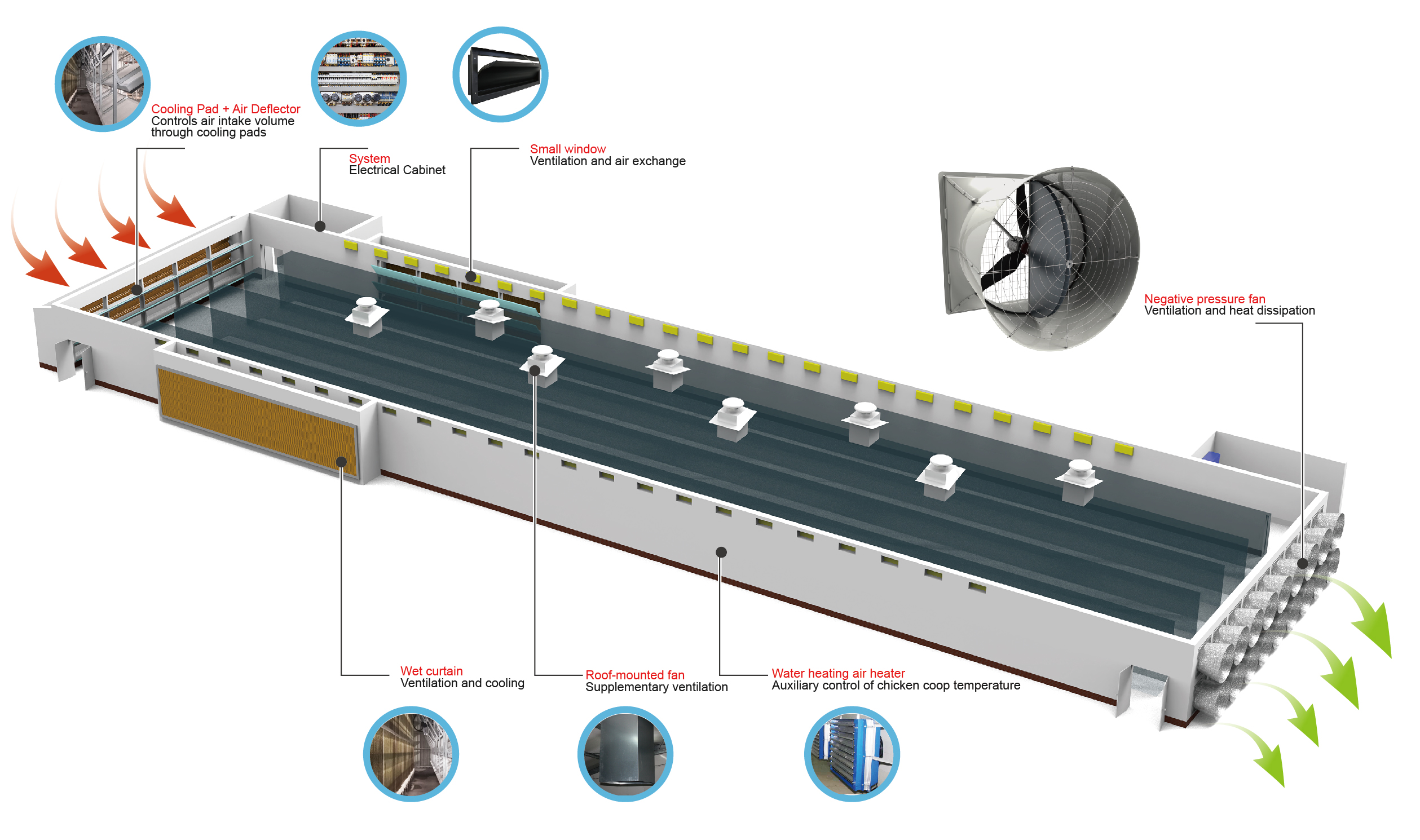

Environmental System

Feeding System

Environment protection

New Zesting assigns a professional project management team to each chicken farm construction project, strictly controlling the construction timeline. During the design and construction phases, comprehensive consideration is given to various factors such as land resources, environmental protection, and biosecurity. By leveraging the latest technologies, the company builds highly informatized, intensive, and intelligent chicken farms for its clients.

Length adjustable to accommodate sows of different sizes; effectively reduces the mortality rate of piglets from being crushed; advanced galvanizing process for anti-corrosion and rust-proofing, ensuring long service life to meet all your needs.

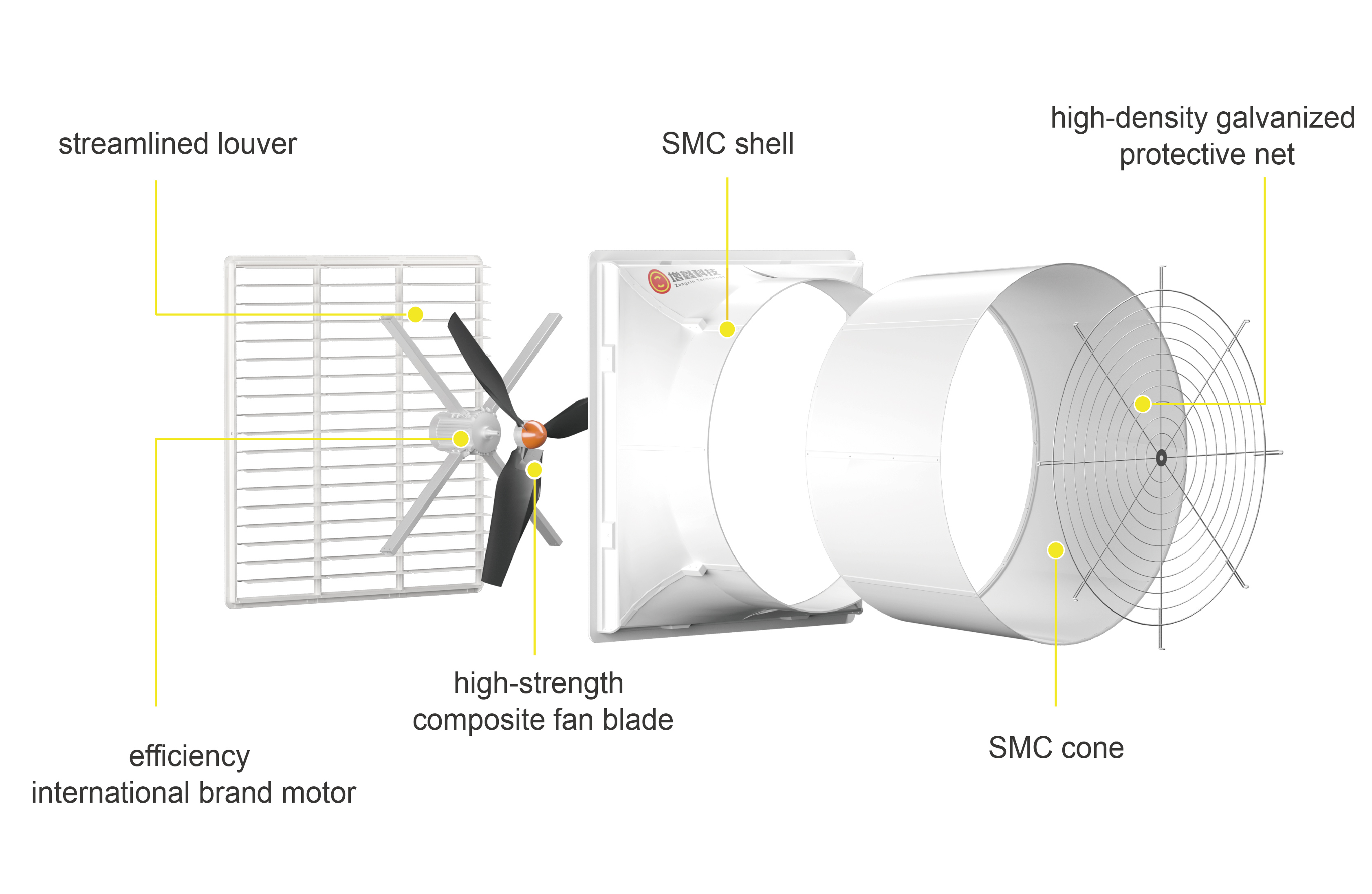

The fan blades are made of high-strength composite materials, offering exceptional strength and rigidity. They exhibit minimal deformation under high negative pressure operation and are suitable for working environments with high humidity and corrosive gases.

The New Zesting Liquid Intelligent Feeding System was developed by the R&D team of New Zesting Co., Ltd. After five years of dedicated research, this system was designed to benchmark against renowned European liquid feed products. It comprises intelligent subsystems for complete feed preparation, fermented auxiliary ingredient selection and mixing, distribution and feeding, and pipeline cleaning. Integrated with an IoT platform, the system operates under computer-controlled automation across all processes. Tailored to the actual conditions of each pig group, it enables fully intelligent operation based on predefined feeding curves, ensuring balanced nutrition and optimal feed-to-meat ratios. The system achieves automated, timed, and quantitative liquid feeding while enabling data collection and management.

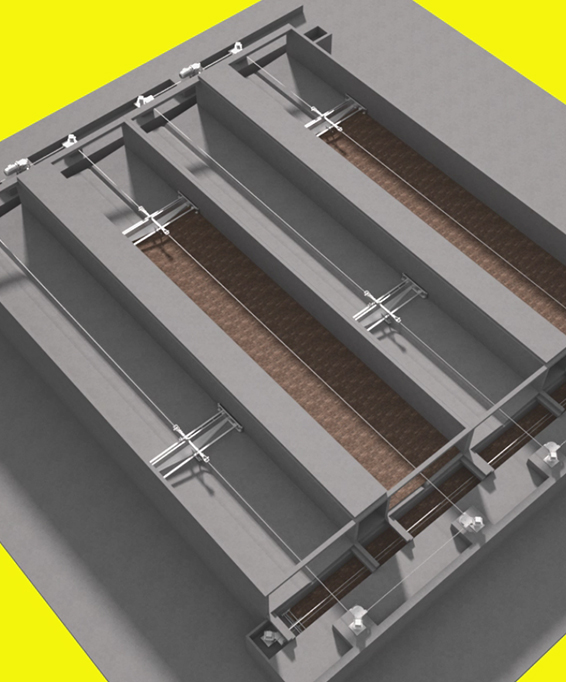

The entire product is made of 304 stainless steel, offering excellent corrosion resistance and a long service life. The hollow design effectively gathers pet waste and prevents uneven force distribution. The bottom features a nylon scraper blade, which is wear-resistant, quiet, and replaceable.

One stop signing is more hassle free!

-SS304 stainless steel material, corrosion resistance, long service life;

-Hollow design, effectively gather manure, prevent uneven force;

-Nylon scraper at the bottom, wear-resistant, silent, replaceable

One stop signing is more hassle free!

As an important part of the efficient, energy saving and intelligent farming system, it mainly includes computer control system & air compression system, silo , water tank, mixing tank, E-weighing device, feeding pump, PVC conveying pipeline, valves, feeding outflow etc. Each part is connected to the central computer through sensors, and each procedure is operated under the control of the computer. Finally it can intelligently run(feeding curve ) to balance feed nutrition and optimize feed ratio according to the actual situation of each herd of pigs.

One stop signing is more hassle free!

Safety: eliminate human contact and feed from outside, avoid the risk caused by vehicle cross-feeding, and ensure nutrition & health;

Efficiency: The whole process is monitored and operated by one person, realizing integrated control and closed management to improve feeding accuracy & quality;

Economy: No need to convey material to the tower by tanker to tower, saving equipment input and manpower allocation;

Adaptability: It can meet the pig breeding in high buildings, as well as long-distance & high-drop material transportation under complex working conditions;

Client First, Providing Safe and Reliable Technology-Driven Farming Solutions!